About The Company

-

1961 - Beginning of the journey

Founding of the Lychen production section as part of the VEB Werkzeugmaschinenkombinat "7. Oktober" in Berlin. We concentrate on exciting metalworking using lathes and milling machines. A warehouse building of the former sawmill in Lychen is prepared as production site.

-

1981 - 1988 Expansion

We need more space. Therefore, in 1981 and 1988, two new production halls with a production area of around 330 square meters and 250 square meters are put into operation. This is where the material cutting department and the company's own paint shop are located. At this time, around 150 people are employed in the company.

-

1991 - Departure

In October 1991, Maschinenbaumechanik GmbH is founded. We are now a subsidiary of the NILES group of companies in Berlin.

-

1996 - Establishment

A year of change and conception of new goals for the company. With new management, the company is adapted to the requirements of the market. At this time about 15 people are employed in the company.

-

2011 - Investment

We take the next step and modernize our production. In 2010 and 2011 we buy a 5-axis machining center (Mazak), a CNC turning/milling machine (Index-Traub) and the necessary mechanical equipment. In total we invest about 750.000 EUR in our production in both years. At this time, about 25 people are employed in the company.

-

2015 - New owner

At the beginning of the year, I.B.U. Projekt GmbH becomes the new owner. At the same time, the company gets a new name: Maschinenbaumechanik GmbH" becomes "MBM Lychen GmbH".

-

2016 - Training

We are adapting our corporate strategy to the requirements of the market and expanding our manufacturing capacities by investing a total of around EUR 675.000. At the same time, MBM Lychen GmbH is opening its doors for training the younger generation. We offer internships, apprenticeships and dual study programs.

-

2018 - Expansion

This year, I.B.U. Projekt GmbH acquires the company shares of MLS Präzisionsteile-Fertigung GmbH based in Neubrandenburg. The company is renamed MLS Präzisionsteile GmbH. At this time it employs 8 people and produces mechanical components on an area of 400 square meters.

-

2019 - Success

This year, MBM Lychen GmbH achieved sales of more than EUR 2.5 million for the first time. In Neubrandenburg, we move into new production facilities with an area of 450 square meters. At the same time, we purchase a new 3-axis machining center (Mazak) and invest a total of around 200.000 EUR in our production at the Neubrandenburg site.

-

2021 - Into the future

MLS Präzisionsteile GmbH and MBM Lychen GmbH are merged. From now on we act together on the market under the name MBM Lychen GmbH. At this time 32 people are employed in the company. For the first time the company achieves an annual turnover of more than 3.0 million EUR. The business association "Uckermark", of which we are a member, selects us as the company of the year 2020.

-

2022 - 60 years Lychen

We have been producing at our site in Lychen for 60 years.

Key Figures

In 2021 we have achieved the following values:Our Standards

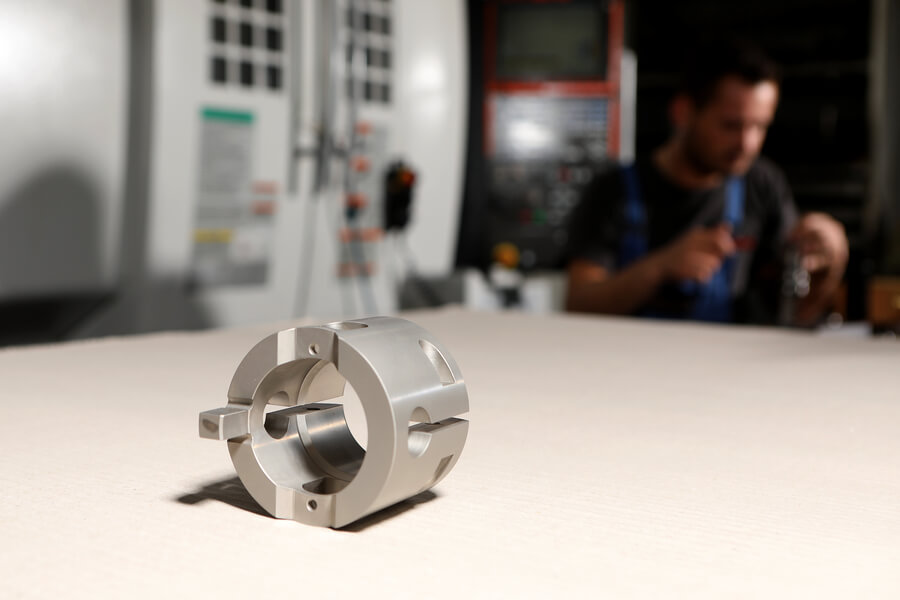

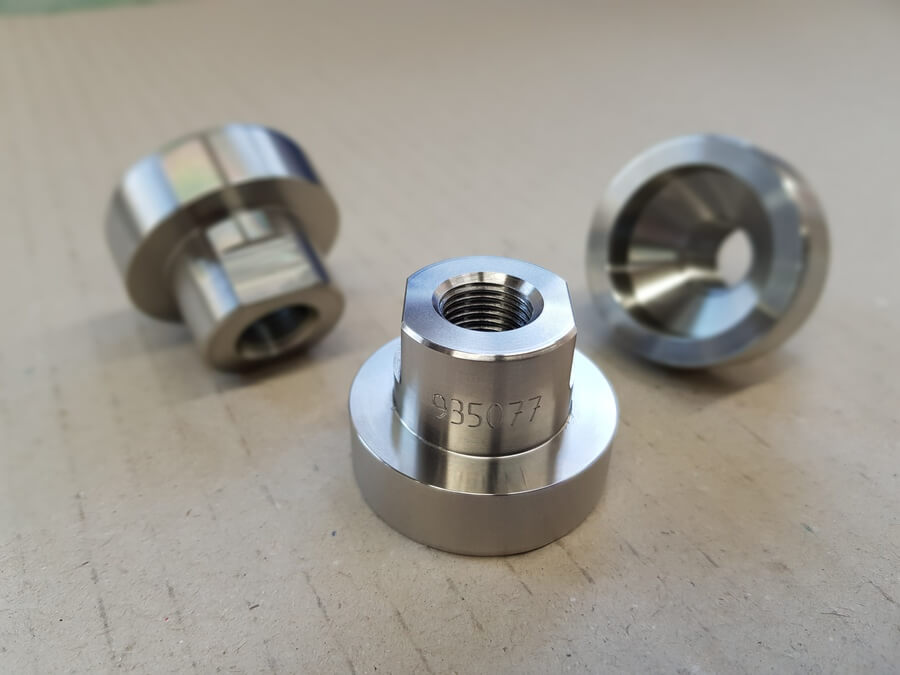

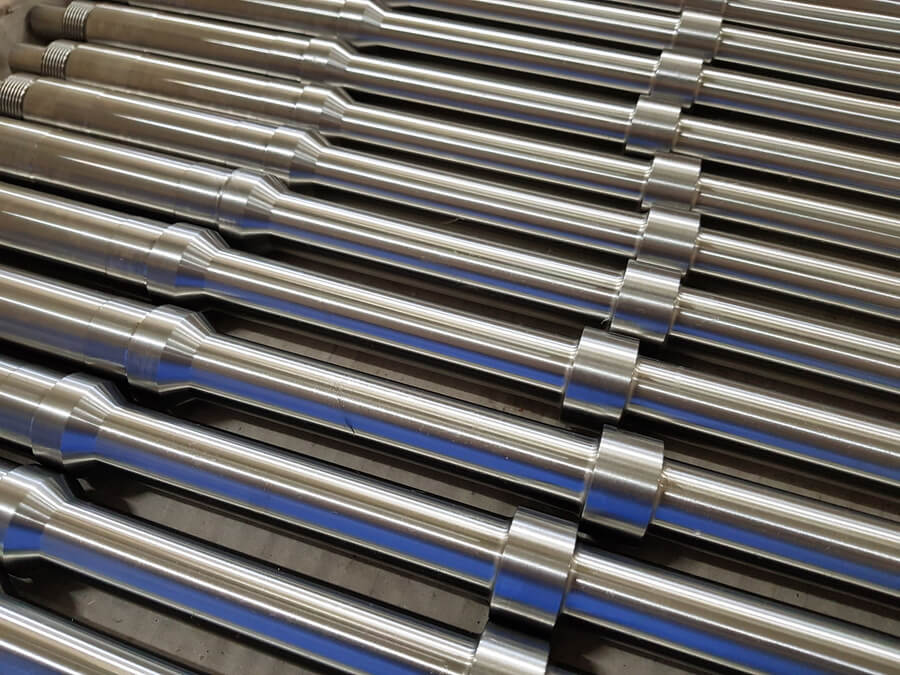

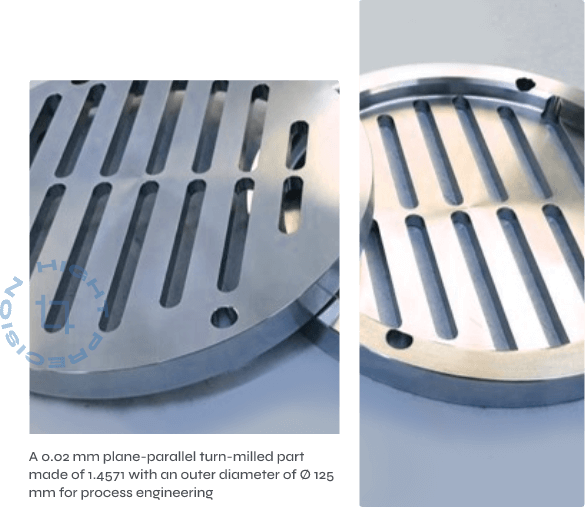

With sound expert knowledge, we manufacture form and position tolerances down to a hundredth of a millimeter. We can produce fits up to and including ISO tolerance field five.

For products with coatings or where the material properties have to be changed, as well as for manufacturing tasks in the single-digit micrometer range, we rely on a network of specialized cooperation partners.

Even if the demands on the product are high - a technical implementation is almost always possible.

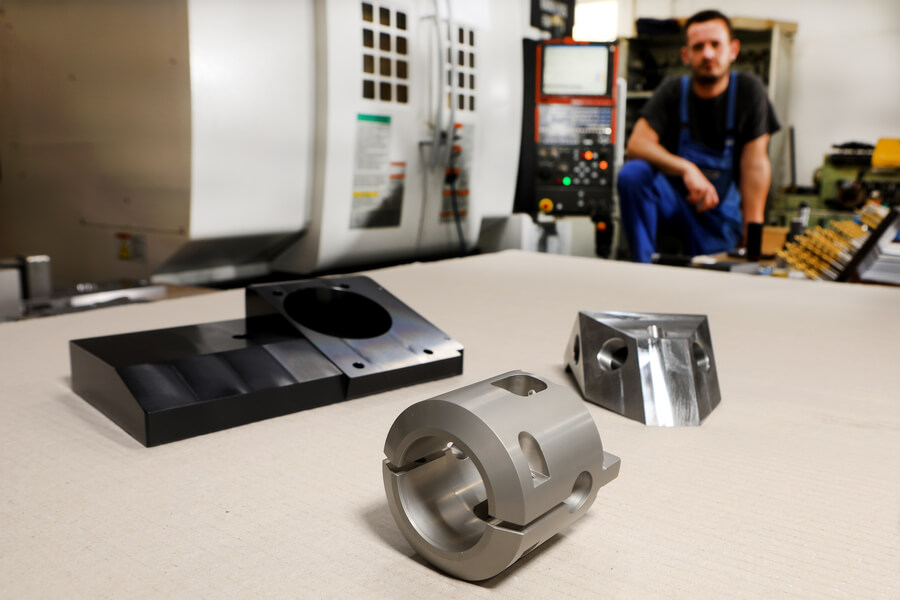

Our Machine Park

| Component base area | Component height | Note | |

|---|---|---|---|

| Turning conventional small | Ø 150 mm | 1.000 mm | X- and Z-axis |

| Turning conventional big | Ø 300 mm | 1.450 mm | X- and Z-axis |

| CNC Turn Milling Centers | Ø 5 mm to Ø 65 mm | 3 mm to 250 mm | X, Y, Z, B, C axes, driven tools, main and counter spindle, travelling tip, bar feeder |

| CNC turning | Ø 350 mm | 3 mm to 1.450 mm | X, Y, Z, C axes, driven tools, steady rest and tailstock with traveling centers |